Designed to achieve extraordinary frying results, designed to simplify the cook's job.

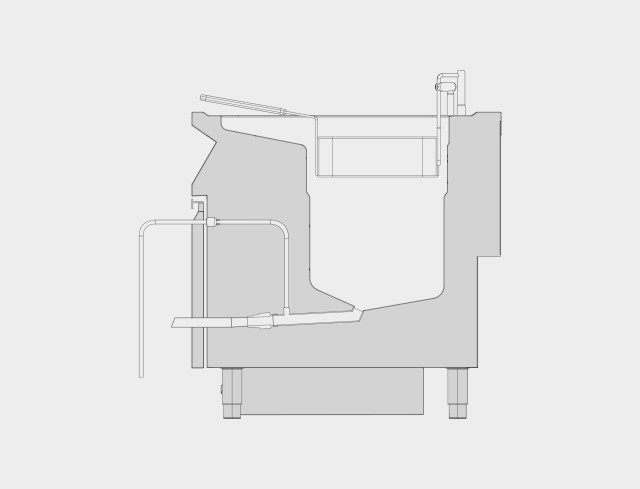

iFry is available with an automated oil filtration function as standard. This process can be activated even while the oil is still hot, up to a temperature of 180°C. The standard duration is 5 minutes at full load, and during the process the oil is filtered of dirt and food residues.

The filtration is carried out through a first metal mesh filter and then through a second, very fine-meshed technopolymer filter. The oil is then pumped back into the tank.

iFry can take care of filling and emptying the tank for you. To do this, there is an additional pipe (supplied as standard) that allows you to empty the used oil into an external container. Filling can be done directly from the container where the oil is stored, and will be pumped into the tank using a special probe supplied. These automated systems mean that the weight of the oil canisters does not have to be borne by the kitchen staff, thus preserving their physical health.

For a thorough and complete cleaning of the iFry, the same external oil drainage system can be used. This avoids contaminating the oil filtering tank with chemical agents that could affect the quality of the oil in subsequent processes, while achieving a complete and thorough cleaning of the entire equipment.

The Cobalt and Wery trademarks are the property of Mareno Ali Group s.r.l., which owns all rights to their use and marketing. It is therefore forbidden to use these trademarks unless expressly approved by Mareno Ali Group, as well as their use on any type of product.